Toyota Motor Manufacturing, Kentucky, Inc., in Georgetown, Kentucky was Toyota's first wholly owned manufacturing facility in the United States. Since 1988, Toyota's Kentucky teams has been building quality vehicles in the Bluegrass state. Today, "TMMK" is the largest Toyota plant outside of Japan. Each year in Georgetown, nearly 7,000 team members build about 500,000 vehicles and engines. That's about 2,000 vehicles every day.

Toyota Motor Manufacturing, Kentucky, Inc., in Georgetown, Kentucky was Toyota's first wholly owned manufacturing facility in the United States. Since 1988, Toyota's Kentucky teams has been building quality vehicles in the Bluegrass state. Today, "TMMK" is the largest Toyota plant outside of Japan. Each year in Georgetown, nearly 7,000 team members build about 500,000 vehicles and engines. That's about 2,000 vehicles every day.

I had looked into taking our families on a tour of the Toyota plant while they were here visiting last week, but the facility was closed all week for their summer break. I also learned that you cannot take children younger than first grade on the tour when I called. With a the arrival of our baby boy fast approaching, I knew it was now or never to take the boys with me and go through. I made an appointment for the four of us for July 21 at 10 AM and got a sitter for the girls (and I never get sitters....).

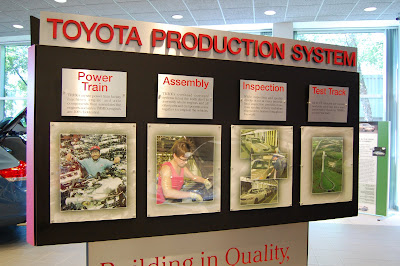

I had looked into taking our families on a tour of the Toyota plant while they were here visiting last week, but the facility was closed all week for their summer break. I also learned that you cannot take children younger than first grade on the tour when I called. With a the arrival of our baby boy fast approaching, I knew it was now or never to take the boys with me and go through. I made an appointment for the four of us for July 21 at 10 AM and got a sitter for the girls (and I never get sitters....).The tram driven tour lasted about an hour and a half. No camera were allowed, but we all looked awesome in our safety glasses and headphones. (Take my word on it.) During the tour we were able to hear and see just what goes into the manufacturing the Camry, Avalon and Venza vehicles that roll of the line each day. Tour guides drove us through portions of the 7.5 million square foot facility. The tour began in Stamping where we saw cars take shape from huge coils of rolled up steel. We then moved to Body Weld where these stamped pieces are put together. We were able to watch as a team of computer-controlled robots performed the welds that result in a completed body shell. Overhead conveyors transport the cars from Paint, to the Final Line in Assembly.

The whole thing reminded me of Star Tours at Disneyland, where robots look like they are making space ships and conveyor belts above your head move parts around the room.

Some of the highlights were seeing the sparks fly in the welding area, watching adult men and women transport items via bike-like tricycles and seeing the automatic guided robots (AGR's) travel unassisted across the plant. It really was cool.

1 comment:

i love all the posts! but seriously, HOW in the world did you do all that in three days?? it was so fun to see you, we need to get together again soon!

Post a Comment